What you will learn in this blog

Highjump WMS has been a relevant player in the Warehouse Management System field. Warehouse Management Systems are critical software solutions that optimizes warehouse operations by managing inventory, order fulfillment, and shipping processes. They enable businesses to enhance operational efficiency and ensure timely product delivery.

What is a Warehouse Management System?

A Warehouse Management System is a comprehensive software solution that enables businesses to manage their warehouse operations from receiving and storing inventory to picking, packing, and shipping orders. It provides real-time visibility into inventory levels, order status, and warehouse operations, enabling businesses to make informed decisions and optimize their supply chain. With a WMS, companies can automate various warehouse processes, reduce manual errors, and improve overall productivity.

What are Modern WMS Solutions

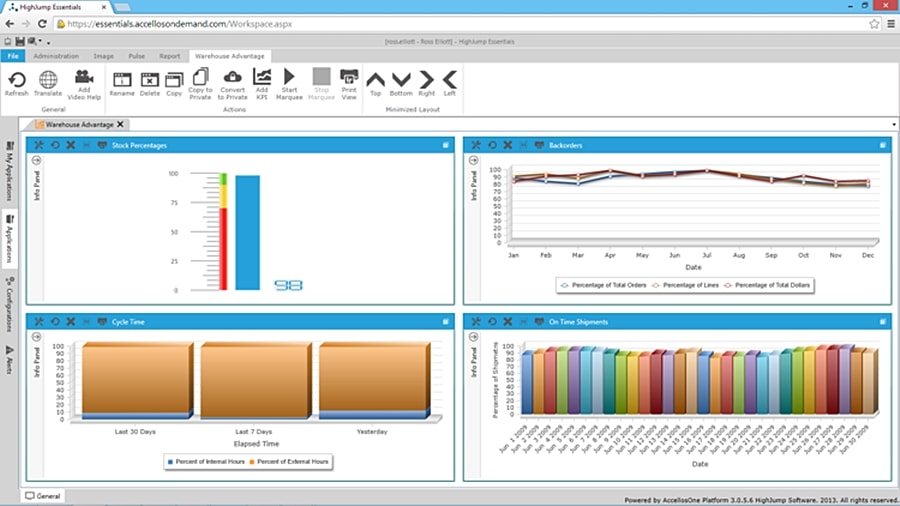

HighJump warehouse management system has been in the warehouse management space since the early 2000s. As businesses grow, many are looking for alternatives that offer similar functionality with more flexibility and modern features.

Warehouse Management Evolution

HighJump WMS and Körber WMS are traditional WMS solutions for big businesses. As a global provider, HighJump software has focused on complex distribution operations and inventory management for years.

Today’s Challenges

Modern warehouse management has moved beyond traditional wms solutions. While HighJump WMS has advanced warehouse management features, businesses are looking for alternatives that offer:

-

Simplified business processes

-

More operational efficiency

-

Real time data

-

Barcode integration

Challenges of Traditional Warehouse Management Systems

Traditional warehouse management systems often rely on manual processes, paper-based documentation, and outdated technology, leading to inefficiencies, errors, and increased costs. These systems can struggle to keep up with the demands of modern supply chains, resulting in:

-

Inaccurate inventory levels and stockouts

-

Inefficient use of warehouse space and labor

-

Delays in order fulfillment and shipping

-

Poor visibility into warehouse operations and inventory levels

These challenges can significantly impact a business’s ability to meet customer expectations and maintain a competitive edge in the market.

System Capabilities

Core Functionality

The warehouse management system space has:

-

Advanced inventory tracking

-

Distribution center management

-

Order processing

-

Supply chain integration

Advanced Warehouse Management Features and Integration

Modern WMS must have:

-

Labor management

-

Yard management

-

Wave planning

-

Transportation

Key Features of a Modern Warehouse Management System

A modern Warehouse Management System should include the following key features:

-

Inventory management: Real-time tracking of inventory levels, locations, and movements to ensure accurate stock levels and reduce the risk of stockouts.

-

Order management: Automated processing of orders, including picking, packing, and shipping, to streamline order fulfillment and reduce processing times.

-

Labor management: Tracking and optimization of labor resources and tasks to improve workforce productivity and reduce labor costs.

-

Yard management: Management of yard operations, including dock scheduling and trailer management, to enhance the efficiency of inbound and outbound logistics.

-

Transportation operations: Management of transportation operations, including carrier selection and routing, to optimize shipping processes and reduce transportation costs.

-

Advanced reporting and analytics: Real-time visibility into warehouse operations and inventory levels, enabling data-driven decision-making and continuous improvement.

-

Integration with other business systems: Seamless integration with ERP, CRM, and other business systems to ensure a unified and efficient supply chain.

Industry Solutions

Manufacturing and Distribution

Both HighJump WMS and Körber WMS serve:

-

Consumer goods

-

Manufacturing

-

3PL (third party logistics) providers, which benefit from the efficiency and cost-effectiveness in managing warehousing and transportation operations. The essential role of technology in optimizing these services is also a key factor.

-

Retail

Technology

Advanced warehouse management features:

-

Serial tracking cross check

-

Real time data

-

Barcode integration

-

System access

Ready to try a more user friendly WMS? Schedule a PULPO WMS demo today

Operational Performance

Business Process

-

Simplified distribution

-

Better inventory management

-

Faster order processing

KPIs

Success factors:

-

Overall efficiency

-

Less training time

-

Better business processes

-

Better warehouse operations

Inventory Management Best Practices

Effective inventory management is critical to the success of any warehouse or distribution center. The following best practices can help businesses optimize their inventory management processes:

-

Implement a first-in, first-out (FIFO) inventory system: Ensure that older inventory is sold or used before newer inventory to reduce the risk of obsolescence and spoilage.

-

Use barcode technologies and RFID tracking: Accurately track inventory levels and movements to improve inventory accuracy and reduce manual errors.

-

Implement a cycle counting program: Regularly verify inventory levels and identify discrepancies to maintain accurate stock records and reduce the risk of stockouts.

-

Use advanced reporting and analytics: Monitor inventory levels and identify trends and patterns to make informed decisions and optimize inventory management.

-

Implement a vendor-managed inventory (VMI) program: Enable suppliers to manage inventory levels on behalf of the business to reduce stockouts and improve supply chain efficiency.

By implementing these best practices and using a modern Warehouse Management System, businesses can optimize their inventory management processes, reduce costs, and improve operational efficiency.

Implementation

System Integration

A WMS must:

-

Integrate with current systems

-

On premise solution

-

Store shelf optimization

-

Distribution center management

Deployment

Modern alternatives to HighJump WMS offer:

-

Flexible deployment

-

Scalable

-

Quick deployment

-

Better support

Try PULPO WMS today - Contact us

Future Proof

Advanced

Modern wms have:

-

Wave planning

-

Supply chain optimization

-

Real time data

-

More operational efficiency

Technology

Key benefits:

-

Advanced warehouse management

-

Better inventory tracking

-

Improved distribution

-

Simplified business processes

Customer Focused

Business Outcomes

The right warehouse management system will give you:

-

More operational efficiency

-

Better inventory control

-

Optimized distribution

-

Better customer satisfaction

Continuous Improvement

Modern WMS have:

-

Ongoing optimization

-

Better business processes

-

Improved management

-

Advanced features

Summary

HighJump WMS and Körber WMS are established in warehouse management but modern alternatives have a lot to offer for businesses looking for a more agile and cost effective solution. It’s about finding a system that fits your business and can grow and adapt to today’s fast paced market.

.png?width=66&name=PULPO_WMS_logo%20(1).png)

PULPO WMS Features

PULPO WMS Integrations

Shopify

WooComerce

Magento

Sendcloud

Subscribe to our logistics newsletter

Get biweekly content with industry trends, technology and tips.

-1.png?width=1000&height=562&name=blog%20image%20(26)-1.png)

-1.png?width=300&name=blog%20image%20(4)-1.png)